Boddington

SMP

July 2023

Newmont

Resources

Project Executive Summary Fact Sheet

Scope

Replace rails over bins & shuttle sweeps.

Tuesday 11th July 2023 – Day Shift

Took crews up to top of HPGR building to scope the work front.

Crews completed JHA’s and other associated documentation.

Tuesday 11th July 2023 – Night Shift

Crews taken up to scope works at the top of the HPGR building and reviewed/ confirmed JHA and other associated documentation.

Crew set up a tarped area at the north end of the HPGR for shelter/tool storage for protection from the inclement weather.

Wednesday 12th July 2023 – Day Shift

Delays with isolations…permits not ready for issue until 10:45am.

The permit for the HPGR shuttle rails needed to be modified to remove confined space controls as it stated it was confined space…but as we would not be working under the shuttle rail, we got CS removed by creating a new permit. Mech & ropes crews were locked on task at 11:50am.

Crew began work around 12pm and began with loosening the guide chains on each side once complete crew used mechanical aid to lift chain off the drive sprocket and lower chains to allow for the removal of the shuttle.

Grease lines were disconnected by mech crew and tagged/bagged ready for shuttle drive removal and the 50nb U-bolts holding the fire suppression lines were removed so the lines could be moved across to allow more clearance for lifting out the shuttle drive module.

Crew attempted to remove hold down bolts which attached shuttle to the head chute but found that the bolts were seized and un-able to rattle off so oxy was used to cut bolts and will need to be replaced when shuttle is to be lifted back in.

Rail clips cut off over bin 3 using grinders to cut off the nut.

Wednesday 12th July 2023 – Night Shift

The night shift sparkies arrived at start of shift

and completed all their works and were out of the area around 2100pm.

With all rail clips cut off over bins 3 and 4, the crew attempted to lift out these sections of rail whilst waiting for the sparkies however the crane wouldn’t lift due to high winds.

Newmont weather alerts were saying wind speed of +36 kph.

Once the sparkies had finished, due to the head shroud over lapping and sitting on the drive module by approximately 100mm we installed a come-a-long on both the east and west side of the drive module and pulled it north to gain clearance. Checked crane ops at 0230am and Boom supervisor advise the wind is still too strong.

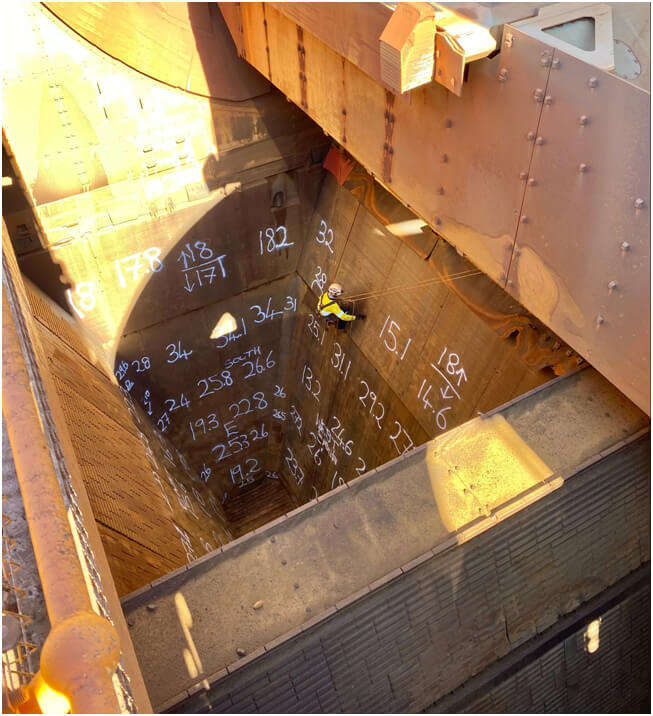

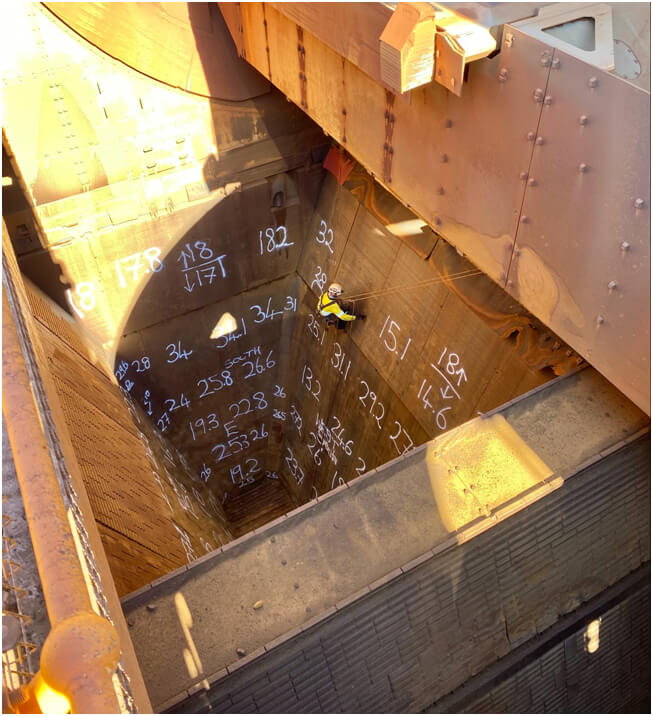

Rope crews took the opportunity to start wear-maxing in bin 4 whilst they are removing clips over the top of bin 2.

100% of rails clips on both rails were removed by 2330pm…besides a few under the shuttle drive module to be removed once lifted out.

The new clip bolts were collected from the LDM, there were 200 ordered and out of the 200 we received 140.

Thursday 13th July 2023 – Day Shift

Crew headed to task straight away and began crane lift of shuttle drive module…with the additional clearance gained with the fire suppression lines moved across, the shuttle was clear and lifted straight out without rotating 90deg.

Shuttle drive module and had it landed to the ground at around 8:30am.

Note: 2 sets of U-bolts were removed each side on the fire suppression line for clearance…however, 3 sets would allow even more for next time.

Once the shuttle drive was lifted out, the crew removed the remaining rail clips over bin 1.

With all the clips off…all the old shuttle rails were lifted out and landed to the ground.

The crew removed all clip bolts, all base plates fully cleaned up and blown out using needle guns and air hoses, rail beams cleaned up/blown down both sides…bins 1 through 4.

Crew lifted in (x2) new 12m rails craned up onto the east side and (x2) onto the west side beams slightly forward of where old rail needs to be cut back to remove worn section, just in case the wind comes up again tonight and lets nightshift continue progress.

The crew also replaced a damaged ladder bracket the chain sits on and stitch welded as required on the east side of the HPGR over bin 1 before shuttle drive module goes back in.

The rest of the missing clips, fish plate bolts and fish tail base plate bolts were craned up to HPGR.

The rail cutting equipment was craned up, set up on the east side and the existing east side rail was cut back approximately 180mm to remove worn section.

Thursday 13th July 2023 – Night Shift

The rail cutting equipment was moved to the east side and using a 3m straight edge on the rail to identify where the rail was to be cut back, the old rail was cut back approximately 600mm with, the new rail pulled back and joined with the fish plate connectors.

Due to there being a 5mm height difference between the old worn rail to the new, spoke to Client who said this was fine and will just need to blend the new rail to the old rail.

The first new section (12m) of rail sections was pulled back/butted up into place each side over bins 1-2 and attached with fish plates…the crew proceeded to align and lock down rails over bin 1 with new clips.

The lube techs were contacted at around 2100pm to gauge a rough time frame for them to complete their works on the shuttle drive and informed them that we want to be lifting it up into place before end of shift.

Spoke to them again at 0230am to inform them that we will be about 1 hour away from wanting to lift the shuttle drive into position, as the lube techs were not finished, we were unable to lift the section.

The remainder of the new rail required over the top of bin 4 both was measured, and the last sections of rail were cut to size on the ground in the crane bay and then lifted into place.

Bin 1, 2, 3 rails on the west side have been aligned, bolted together with fish plates and locked down with rail clips and are 100% tightened.

Crew demobilised most of the tooling and equipment to the ground and disassembled the shelter form north end of HPGR.

Friday 14th July 2023 – Day Shift

Got clarification on the 6mm step up from old rail to new on the east side around 9am by Newmont and confirmed by the engineers to taper it back 100mm. Then proceeded to complete tapers.

East side rails were positioned and clipped into place over bins 2 and 3.

The shuttle drive module was lifted onto rails 11:30am.

During the installation of shuttle, it was identified that lube crew have secured manifold in a new position which had to be removed as it was installed in a location that would not allow shuttle to connect to head chute.

The shuttle was then lifted approx. 100mm and using a come-a-long each side from shuttle-to-shuttle drive, the module was pulled/rolled back into position and bolted up.

West side rail clips had to be loosened so the rail could be pulled back to close a 10mm gap (not accepted by Newmont) at the second new joint and then re-clipped down.

The fishtail bolts found on site needed to be modified to fit.

An issue with 2 rail clips fouling up on the fishplate bolts was identified where new rails had been installed, so x2 of the rail clips were modified slightly to allow them to fit.

Friday 14th July 2023 – Night Shift

The crew proceeded to relocate chains over drive sprockets on both sides and re-tension.

All rail clips checked and confirmed.

Electrical re-connection and scaffolding for scrapers has been completed.

Rail sweeps 100% completed.

With all rail works completed, the ropes crews took the opportunity to get into bins 2 and 3 to complete the wear-max.

Saturday 15th July 2023 – Day Shift

The deluge lines were repositioned on both sides of shuttle drive with U-bolts and damaged sprinkler being replaced.

All x4 chain tensioners, U-bolts replaced along the fire suppression lines and head chute bolts have been Denzo’d to allow for easier maintenance in the future.

Once all shuttle rail works and rail sweeps had been checked off and approved by NBG, the crew proceeded to re-install the doors/guards on both sides of HPGR.

Once the extra emergent works wear-maxing bin 1 was complete, the last of the were re-installed.

Saturday 15th July 2023 – No Night Shift

Sunday 16th July 2023 – Ropes Core Crew Day Shift

Completed the rest of demobilisation to tool container from crane bay.

Other Projects

VIEW ALL PROJECTS

Learn from

the best

Our range of nationally recognised training ensures workforces are meeting mandated licencing and legislative requirements. We help individuals to gain skills that enable them to confidently step into project teams.

VIEW TRAINING COURSES

Have a project in mind?

Our dedicated team is committed to achieving high-quality, efficient and safe project outcomes.